Bread Crumbs Extruding Line

Introduction:

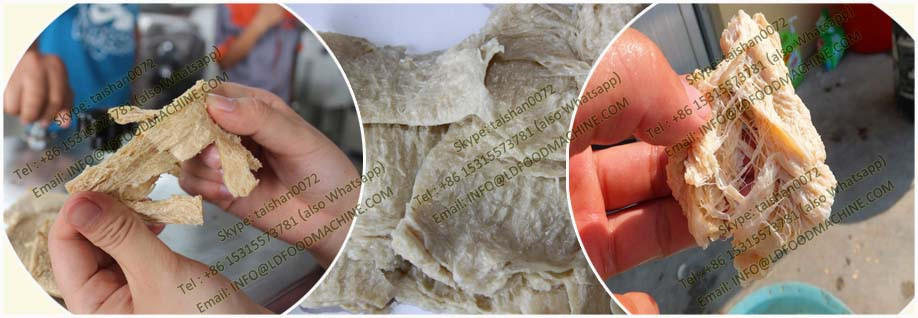

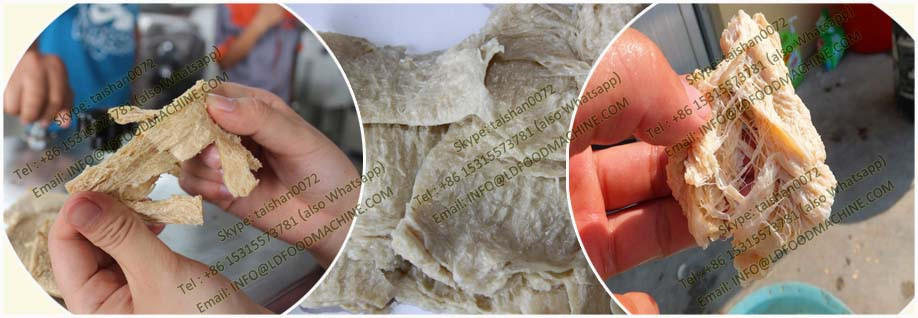

The Bread Crumbs Extruding Line can produce crumb in different granularities which can be used in fried chicken, on the bread, etc. Crumb is mainly for friend beefsteak chicken as frying dressing. This line is specially designed and developed to operate from the material mixing to final shaping automatically. Little manpower, without waste, lower production cost, higher production efficiency.

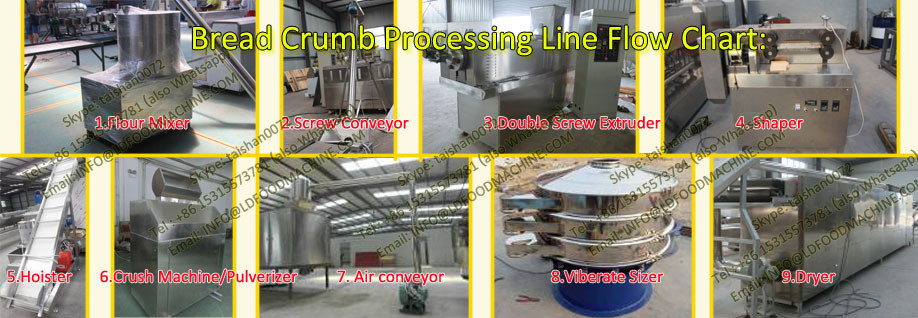

Production Process Line:

Mixer---Twin screw Extruder—Automatic Feeder—Cutter—Conveyor—Pulverizer—Z-Shape Conveyor—Crumbs Sieve—Dryer(Extended)

Basic Formula:

wheat flour/corn starch/corn powder

Machine Parameters:

Model |

Installed Power |

Power Consumption |

Capacity/Output |

Dimension |

SP65-II Twin Screw Extruder |

42.9kw |

30kw |

100-180kg/h |

3070x960x2050mm |

SP65-III Twin Screw Extruder |

31.3kw |

22kw |

100-150kg/h |

2600x960x2000mm |

SP70-III Twin Screw Extruder |

64.45kw |

40kw |

200-250kg/h |

3320x960x2100mm |

SP75-III Twin Screw Extruder |

79.05kw |

50kw |

250-350kg/h |

4650x1100x2200mm |

SP85-III Twin Screw Extruder |

97kw |

72kw |

350-500kg/h |

4800x1100x2300mm |

SP52-II Twin Screw Extruder |

54.3kw |

40kw |

100-150kg/h |

4500x900x1820mm |

SP75-II Twin Screw Extruder |

89.7kw |

67.3kw |

200-350kg/h |

5200x1100x2200mm |

SP90-I Twin Screw Extruder |

161.3kw |

121kw |

350-800kg/h |

5800x1200x2500mm |

Machine Advantages

- Productive: Automated systems for controlled and consistent production on a continuous basis, easy and quick product changeover, automated start up, simple cleaning and maintenance procedures.

- Flexible Formula: Processing of a wide range of raw materials, such as corn, wheat, rice, potato, oat etc;

- Widly Appication: Easy adaptation to extend the range of products by changing the segments screw;

- Smart Control System: PLC Control of production to ensure optimized process parameters for each recipe;

- Advanced Die and Cutting system: This designs give processors an entirely new set of templates to create innovative shapes and sizes-Balls, animals, stars, rings, pillows, triangles, curls, chips, sticks, and also letters;

Processing & Factory

Our services:

- Before Purchasing: We will provide professional technical project and sales consultation service to solve the customers' question and worried;

- During Production: Timely updates the machine status for customer to ensure delivery time, and quality

- After Production: Machine testing video and photos will be provided for inspection, if the customer can't come;

- Before & During Shipment: The machine will be cleaned and packaged before transportation; All the documents will be provided for the seller;

- Installation & Training: Providing professional and expert technical engineers to supply the training and installation service.

- After Sales Service; Dedicated department and engineers for providing the timely and efficient service when the clients' need, such as formula, parameters setting, and spare parts;

Packaging & Shipping

- All Machine will be cleaned and whole wraped by plastic film to avoid any scratch;

- Extra Spare Parts,wires and tool box will be placed with the package;

- Delivery Department and sales will check the list to avoid any missing;

- All Wooden Cases for protecting the machine during long-time shipment;

FAQ

FAQ

1 Where is your factory?

Jinan city, Bread Crumbs Extruding Line/Automatic Nugget Forming Machine/Bread Crumb Crusher

2 What is your machine warranty?

1 year, main parts warranty time will be 2 or 3 years.

3 Do you supply spare parts?

Yes, we supply spare parts with reasonable price;

4 What can you provide for after sale service?

We can send engineers to your factory for installation and training if customers‘ required.

5 If we show you our layout of factory, can you help to design the whole process line?

Yes, our experienced engineers and technical employee can help you to arrange the layout and installation of whole process line based on your real situation;

6 How can we contatc you if we meet problems during production?

Phone/email/wechat/whatsapp/Skype are all available.

7 If we have samples of new products, can you help to analysis and design the machine?

Yes, Our technical department can help to analysis, design and test the new products you offered.

Related Products

What is hot?

Puff Snack/Corn Snack/Extrusion Snack 2D/3D Pellet, Fryums, Bugles Snack

↑ Point ↑ Point

American Popcorn/Caramel Popcorn Double Screw Extruder

↑ Point ↑ Point

Contact

Jinan Joysun Machinery Co., Ltd. est une société spécialisée dans la production d'extrudeuse alimentaire à double vis, d'extrudeuse monovis, d'équipements de torréfaction et de stérilisation à micro-ondes, etc. Bien que basée sur le marché domestique, l'entreprise ouvre et exploite positivement le marché étranger. Jusqu'à présent, nos produits Bread Crumbs Extruding Line/Automatic Nugget Forming Machine/Bread Crumb Crusher ont été exportés de nombreux comtés et régions, y compris la Russie, l'Europe, l'Afrique, la Corée, l'Indonésie, l'Ouzbékistan et la part de marché augmente progressivement d'année en année. Jinan Joysun Machinery Co., Ltd. continuera à être agressif, créatif et apporter une contribution au développement de l'industrie alimentaire de notre pays avec ses pairs à la maison et à l'étranger.