Automatic Twin Screw Extruder Bread Crumb Production Line

Introduction (application)

As an auxiliary food material, breadcrumbs production line is widely used for fried food to retard that foods are fried into burned, and based on its own performance, crisp exterior could be achievable, usually used as an auxiliary oil food material for beefsteak, fried chicken, etc. In accordance with market demand, our company researched and developed a flow automatic production line integrating with adding raw materials, puffing, creating crumbs and drying. This production line has the advantages of less workers, reused remainders, no-waste, low cost and high efficiency. Its main types include needle scraps, particle scraps, needle crumbs and particle crumbs.

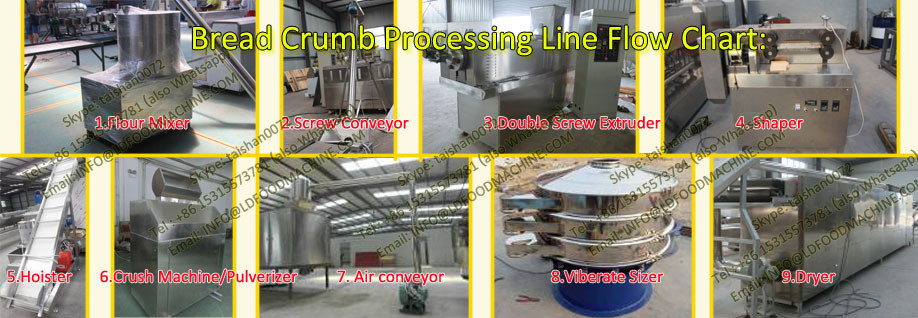

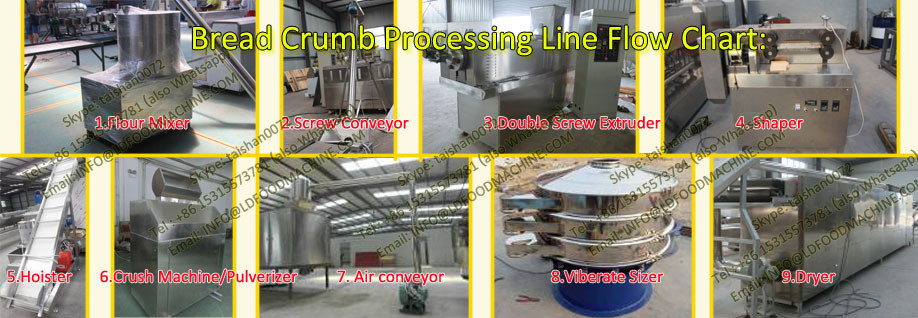

Technological Process

Raw Material Configurations→ Mixing→ Conveyance→ Cutting & Shaping→ Conveyance→

Crumb Pulverizing→ Sieving Crumbs→ Conveyance→ Drying→ Multi-layer Vibrating Screening

Characteristics

Various models to meet different output capacity requirements.

Flexible configurations to meet different produce, budget and workshop layout requirement.

Vast raw material range to produce different final products by only one production line.

High automation and accurate control system to save labor cost and improve the quality of final products.

Independent temperature control system is able to realize zone temperature control, electronic induction, accurate & visual digital display.

Feeding system without material returning. It is unnecessary to clean barrel and screw in case of restarting or material replacement.

Screw adopts high-performance nitride alloy steel with strong wear-resistance and Automatic Twin Screw Extruder Bread Crumb Production Line service life.

Food-grade stainless steel. Neatness and easy clean.

Technical Parameters

Model |

Output Capacity |

Installed Capacity |

Power Consumption |

Dimension Size |

Supply Voltage |

GY13/65-2 |

100 ~ 150 Kg/h |

70KVA |

25Kw |

17.4*1.4*1.8M |

380V/50Hz Three phases or 220V/60Hz Single phase |

GY13/65-4 |

150 ~ 220 Kg/h |

87KVA |

32Kw |

18*1.4*1.8M |

|

GY13/70-1 |

150 ~ 260 Kg/h |

120KVA |

42Kw |

18.9*1.4*1.8M |

|

GY1/75-1 |

200 ~ 400 Kg/h |

208KVA |

60Kw |

24x1.6x1.8M |

|

GY1/85-1 |

250 ~ 500 Kg/h |

234KVA |

85Kw |

24x1.7x2.1M |

Workers

Normally 1-2 operators are sufficient for production.

Samples

Packaging & Shipping

Our Services

Company Information

Jinan Automatic Twin Screw Extruder Bread Crumb Production Line Machinery & Equipment Co., Ltd.(GY Machinery)is the professional manufacturer for advanced and high-quality food machinery.

GY has an expert team with around 15 years experiences in food machine industry. We constantly research extrusion technology and explore food process in order to benefit our clients producing better and creative food.

After years of research, GY has different production lines with different output capacities to meet different customer requirements:

1. Direct Puff Automatic Twin Screw Extruder Bread Crumb Production Line Process Line

2. Breakfast Cereal & Corn Flakes Process Line

3. Core-Filling Automatic Twin Screw Extruder Bread Crumb Production Line Process Line

4. 2D Pellet Automatic Twin Screw Extruder Bread Crumb Production Line Process Line

5. 3D Pellet Automatic Twin Screw Extruder Bread Crumb Production Line Process Line

6. Cheetos/Kurkure/ (Nik) Naks/Corn Curls Process Line

7. Triangle Chips/ Doritos/Tortilla Chips/Pringles Potato Chips Process Line

8. Fried Wheat Flour Snacks/Salad/ Crispy Chips/Bugles/Rice Crust Process Line

9. Natural Potato Chips / Crisps / French Fries Process Line

10. Pasta/Macaroni Process Line

11. Nutritional Rice/ Artificial Rice Process Line

12. Nutritional Powder/Baby Food Process Line

Modified Starch Process Line

13. Bread Crumb Process Line

14. TVP/TSP/Soya Protein Process Line

15. Pet Food/ Dog Food/ Cat Food/ Fish Food Process Line

16. Biscuit Process Line

17. Instant Noodle Process Line

18. Meat / Seafood/ Vegetable Fast Food Process Line

Burger Patty/ Chicken Nuggets/ Chicken Popcorn/ Fish Fillet Process Line

Our Customer

Components & parts

FAQ

Contact

Jinan Joysun Machinery Co., Ltd. est une société spécialisée dans la production d'extrudeuse alimentaire à double vis, d'extrudeuse monovis, d'équipements de torréfaction et de stérilisation à micro-ondes, etc. Bien que basée sur le marché domestique, l'entreprise ouvre et exploite positivement le marché étranger. Jusqu'à présent, nos produits Automatic Twin Screw Extruder Bread Crumb Production Line ont été exportés de nombreux comtés et régions, y compris la Russie, l'Europe, l'Afrique, la Corée, l'Indonésie, l'Ouzbékistan et la part de marché augmente progressivement d'année en année. Jinan Joysun Machinery Co., Ltd. continuera à être agressif, créatif et apporter une contribution au développement de l'industrie alimentaire de notre pays avec ses pairs à la maison et à l'étranger.