LUERYA Full automatic 200-250kg/h capacity P2018 New Bread Crumb/Panko Production Line type bread crumb making machine

Bread crumbs is a widely used food additive for deep fried food, and mainly for frying food surface, such as: fried chicken, fish, seafood (shrimp), chicken, chicken wings, onion rings, etc. Its feature is crispy soft, tasty, delicious and nutritious.The processing line replaces the traditional production technology.

2018 New Bread Crumb/P2018 New Bread Crumb/Panko Production Line Production Line Bread Crumbs production line is effective with less waste materials.Through mixing,cooking,crushing and sifting ,this processing line can make various shapes and sizes bread crumb ,such as Japanese long needle shape,US granular shape, Snowflake shape and so on.

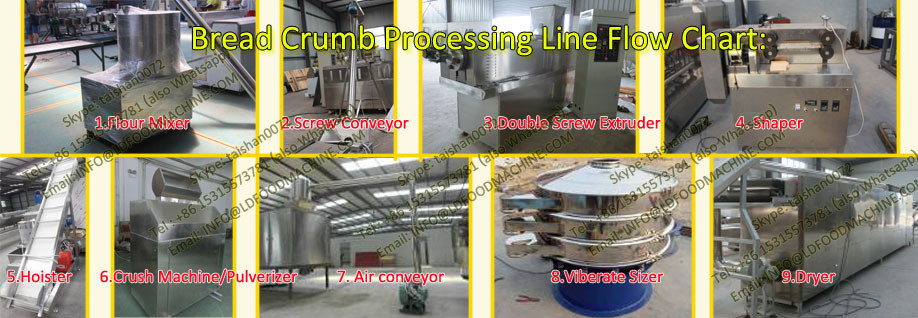

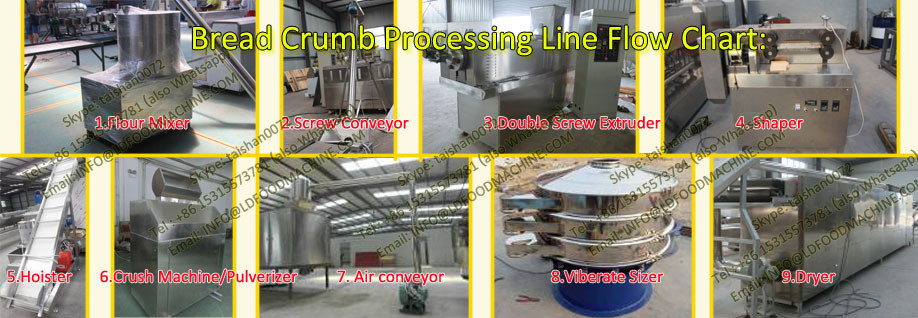

Flow chart of bread crumbs production line and it`s samples:

MIXING SYSTEM -- EXTRUDING SYSTEM -- PULLING AND CUTTING SYSTEM -- DRYING SYSTEM -- CRUSHING SYSTEM --- SELECTING SYSTEM

Technical meter

| Model | Installed power | Power consumption | Throughput | Dimension |

| SX65 processing line | 65kw | 45kw | 120-150kg/h | 25x1.0x1.8m |

| SX70 processing line | 84kw | 63kw | 200-300kg/h | 29x3x3m |

| SX85 processing line | 120kw | 80kw | 300-500kg/h | 30x3.2x3.5m |

| SX90 processing line | 167kw | 125kw | 800-1000kg/h | 35x3.2x3.5m |

Feature

- This processing line takes a new process for bread crumbs production. It is from powder for wheat flour to bread crumbs automatically. No bread produced during the whole process. So no bread crust appeared. The final product is bright white and with good texture.

- The output of our bread crumbs processing line is very reasonable: it can be (120-1000kg/hr).

- And the operation is very simple, the production time is within 20 minutes from raw material to final product.

- Allocation of Breadcrumb Processing Line as reference(not fixed): Mixer-Screw conveyor-Twin screw extruder-Cutter-Hoister-Humid crusher-Air conveyor-Multi-layer roasting oven-Air conveyor(or 2018 New Bread Crumb/P2018 New Bread Crumb/Panko Production Line Production Line feeding machine)-Grading sifter.

Catalogue

Puffed 2018 New Bread Crumb/Panko Production Line Fried pellet 3D&2D 2018 New Bread Crumb/Panko Production Line instant noodle

processing line processing line processing line

pet food bread crumb corn flakes

processing line processing line processing line

Our advantage

1. Superior quality with reasonable prices:

Superior quality with reasonable prices : Shandong LUERYA is ISO certified, quality assured, and priced reasonably. Machine specifications are customized to fit international markets and customer demands. All of LUERYA's machine parts, electronic components, and safety devices follow CE regulation.

2.Tailor made to client requirements:

LUERYA suggests suitable machines per each customer's product requirements. Machine frame bases, functional parts, and mold modifications and customizations are also available for each client's special demands. For example,LUERYA's best seller, the Multi Purpose Extruding Machine, SX-65 not only has hundreds of standard and special shape molds for reference, but also can have Multi-function capacity for producing other product like breakfast cereal,pet food, artifical rice,baby food and so on by changing the formula and producing technical parameter. Client satisfaction is LUERYA's main goal.

3. Supply recipes that are suitable for 2018 New Bread Crumb/P2018 New Bread Crumb/Panko Production Line Production Line machines:

Since 1990, LUERYA has successfully developed many recipes accepted by international markets. Detailed start-up recipes are also included in our machine and service packages for client reference.

4. Timely response and follow-up service:

LUERYA will respond to customer phone calls, e-mails or faxes for machinery or production problems within 24 hours to prevent a client's potential loss.

5. Fully equipped test workplace

In our test workplace, a wide range of flours, food additives, seasonings, fillings, and relative processing machines such as mixers, vegetable cutters, hydro extractor, steamer, baking ovens, as well as other cooking devices are ready for on-site client testing to ensure the machine fits each client's final product requirements.

6. The widest product range available and the soundest specifications selectable.

7. Available for both the semi-automatic production line and turn-key project:

In response to the rise of emerging markets, LUERYA has developed semi-automatic production lines at lower investment capitals to process primary agricultural products into higher value-added snacks foods with 2018 New Bread Crumb/P2018 New Bread Crumb/Panko Production Line Production Line shelf lives or baked snacks. We can also customize high capacity automatic production lines for clients. In addition to factory planning, raw material processing, production line planning, production process optimization, and new product development, LUERYA can also integrate other related quality reputed and cost reasonable Chinese suppliers to complete the turn-key project for you. Through single contact window, LUERYA handles order placing, machine inspecting, crating, and commissioning as well as after-sales servicing all together for clients to prevent hassles from placing orders separately and to drastically save clients the shipping costs, import document expenses, inland transportations, and the commissioning costs from respective suppliers. After-sales service to be conducted by only LUERYA will ensure the clients face no issues and concerns regarding communication and maintenance capability, so that clients can receive timely responses and fast parts.

8. Successfully exported worldwide:

Since 1990, LUERYA has successfully exported its machines to 90 countries. With many practical experiences, LUERYA can provide clients with the most effective market information and customer service experience.

9. Complete parts safety stock for all machine series:

Except for special parts, we can deliver the components each client needs right away.

10. Professional R&D team:

Our specialized R&D teams are constantly developing new machines, effectively fabricating tailor-made machines, and working to improve machine quality.

Packaging & Shipping

Shandong LUERYA Inflating Machinery Co., Ltd. has more than 20 years experience. Initially we produced only food extruder production line which like Puffed snacks, Fried pellet snacks, this had since been extended to a full range of high-tech food extruder processing machinery including Pet food, Floating fish food,bread crumb,Nutrition power baby food ,Denaturated starch,Breakfast cereal/corn flake, Fried instant noodle, VF food /2018 New Bread Crumb/P2018 New Bread Crumb/Panko Production Line Production Line fried vegetable and fruit, Fresh potato chips,and other auxiliary machines.

To provide comprehensive service and to help improving production efficiency for our clients, LUERYA supply them not only individual machines, but also can provide turnkey project from factory planning, raw material processing, production line planning, production process optimization, new product development and customization…series of solutions to satisfy clients every need.

WELCOME TO SHANDONG LUERYA

Jinan Joysun Machinery Co., Ltd. est une société spécialisée dans la production d'extrudeuse alimentaire à double vis, d'extrudeuse monovis, d'équipements de torréfaction et de stérilisation à micro-ondes, etc. Bien que basée sur le marché domestique, l'entreprise ouvre et exploite positivement le marché étranger. Jusqu'à présent, nos produits 2018 New Bread Crumb/Panko Production Line ont été exportés de nombreux comtés et régions, y compris la Russie, l'Europe, l'Afrique, la Corée, l'Indonésie, l'Ouzbékistan et la part de marché augmente progressivement d'année en année. Jinan Joysun Machinery Co., Ltd. continuera à être agressif, créatif et apporter une contribution au développement de l'industrie alimentaire de notre pays avec ses pairs à la maison et à l'étranger.