Product Description

Brief Introduction of bread crumbs making extruder

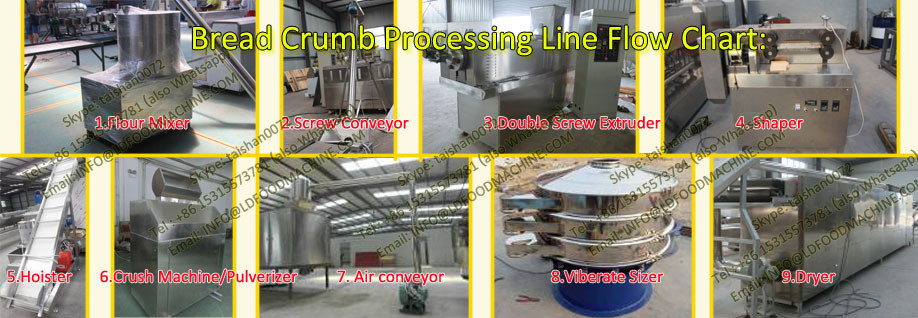

Bread crumb is the widespread use food increase supplementary,mainly uses in thr western-style food exploding the beefsteak,exploding the chicken leg and so on to fry in oil the supplementary material.Our company developsthe development"bread crumb' special-purpose production line production changed the traditional bread crumb technique of production,invests from the lining to destroys the formation is the production-runs,the personnel are few,the excess stock might duplicate uses,does not have the waste material,to reduce the production cost,to raise the labor productivity.Main product acicular crumb,granular crumb etc.Flow chart

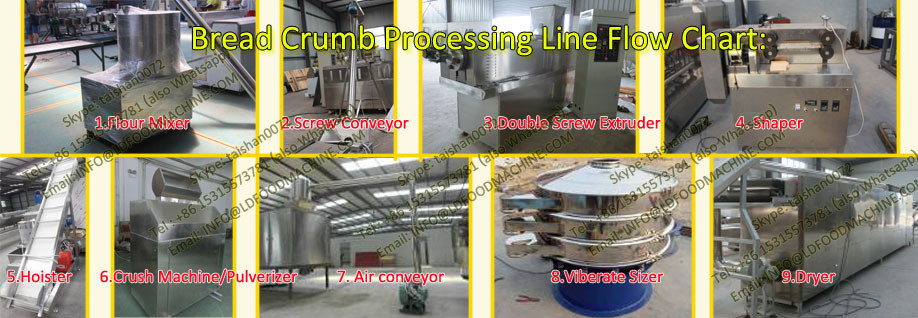

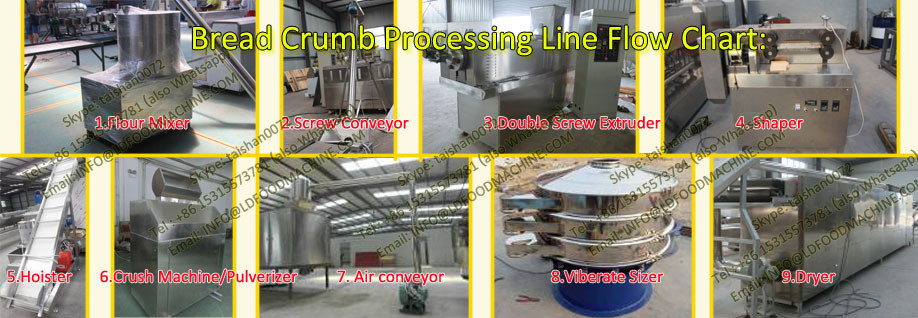

Mixer - Screw conveyor - Twin screw extruder - Cutter - Hoister - Humid crusher - Air conveyor - Multi-layer roasting oven - Air conveyor(or Automatic high efficient needle bread crumbs making extruder feeding machine) - Grading sifter.

| Model | KLD65 | KLD70 | KLD85 |

| Installed Power | 81Kw | 100Kw | 185Kw |

| Production Capacity | 140- 160Kg/h | 240- 260Kg/h | 500 Kg/h |

| Dimension | 21.5*2*2 m | 22*2*2.5 m | 28*2*3.5 m |

Mixer

It is a Mixer which can mix all the raw materials (powder form) with water and liquid chemical additives.

Capacity: 20-30kgs per batch.

Screw Conveyor

The mixed materials can be conveyed in the stainless steel roller to the feeding machine (feeder) of extruder without any leaking, dusting and pollution; Feed quantity and speed is even and stable.

Extruder

The Twin-screw extruder is made of the feeding system, extruding system, cutting system, heating system, transmission system and controlling system.

Dryer

It is used for drying. The net belt running speed can be controlled to change the food drying time in the dryer. Multi-layer dryer is with compact size than other type dryers.Cutter

There are three sets rollers and fixed-length cutting system. With the frequency conversion, you can get broad cutting scope. When using shaper, the cover of the extruder is not used and please put the cover away.Crusher

Material is fed through the inverter feeder crushing cavity, by roller pressing, cutting, grinding to achieve ultrafine grinding of materials.Sample PicturesThe main product are aciculate crumbs, granular crumbs etc.

Packing & Delivery

Packing & Delivery

Packing

Inside: plastic bag for the new design hot selling bread crumbs pAutomatic high efficient needle bread crumbs making extruder production line.

Outside: wooden case (adopt the wooden case or wooden pellets depended on clients' requirement).

Transportation

Shipping, train, express, or upon clients’ demands.

1). Free consultation service before, during, and after sales;

1). Free consultation service before, during, and after sales;2). Free project planning and design services;

3). Free installation and commissioning of equipment until everything is functional;

4). Free management of equipments' long distance shipping;

5). Free training of equipment maintenance and operating personally;

6). Free new production techniques and formulas;

7). Provide 1 year complete guarantee and life-time maintenance service;

8). Engineers available to service machinery overseas.

9). Provide technical exchanging

10). Provide English Version of Installation/Operation/Service/Maintenance Manual

About Us

Jinan Kelid Machinery Co; Ltd. is a professional supplier of food processing machines. Our company's Motto is: "Technology Makes Easy". We offer to cooperate with our customers for mutual and beneficial development.

Jinan Kelid Machinery Co; Ltd. is a professional supplier of food processing machines. Our company's Motto is: "Technology Makes Easy". We offer to cooperate with our customers for mutual and beneficial development. We have through the years established good working relationship with some reputable organizations both at home and abroad with outstanding goodwill.Our main products line include food extrusion machine, soya meal/meat processing machines, industrial micro wave oven, packaging machines, rice cake machine etc. Most importantly, we also provide formulas, technology supports, machine inspection service, etc.

Clients With Us

Clients With UsWe have through the years established good working relationships with some reputable organizations both at home and abroad with outstanding goodwill. Our clients will have a good trip and happy coorperating experience with us, Jinan Kelid Machinery Co., Ltd.

If you have any questions about the new design hot selling bread crumbs pAutomatic high efficient needle bread crumbs making extruder production line, please don't hesitate to contact with us. We are looking forward to your inquiry and make a long business relationship with you in the future!

Jinan Joysun Machinery Co., Ltd. est une grande entreprise par actions, axée sur la production d'Automatic high efficient needle bread crumbs making extruder, intégrée à la recherche scientifique, à la production et aux ventes. La société est située dans la zone industrielle de Shandong salut-technologie, couvre une superficie de 50.000 mètres carrés, avec 15.000 mètres carrés deux standard usine industrielle lourde, plus de 160 ensembles toutes sortes de traitement des métaux de grande et moyenne taille, soudage, équipement d'assemblage .Jinan Joysun Machinery Co., Ltd. attache une grande importance aux échanges techniques et à la coopération internationale, a présenté la technologie de pointe sur et artisanat des États-Unis, Allemagne, Australie et autres pays, établit les lignes de production avancées internationales AAAA et base d'essai moderne de première classe.

Jinan Joysun Machinery Co., Ltd. basé sur une forte résistance technique, l'amélioration des méthodes de détection, excellent système d'assurance qualité pour assurer que « la qualité d'abord, le premier client », responsable de l'installation et la mise en service, les services techniques et des produits de formation technique, après l'installation est terminée je vais 9999999 techniciens vos opérations de production de l'entreprise du personnel de l'équipement de formation professionnelle et technique et des démonstrations en direct.