Brief introduction of roller charcoal briquette machine:

Roller charcoal briquette machine is mainly used to press one kind or several kinds of charcoal powder, etc, that mixed with a certain proportion of binder, to charcoal briquettes which with certain shape and certain physical and chemical properties. It is one kind of the most popular charcoal briquette molding equipments both in domestic and overseas markets. The charcoal briquettes that pressed by our roller charcoal briquette machine with the merits of good burning effects, energy saving and environment protestion, easy for storage and convenient for transportaion, etc.

In order to enhance the intensity of pressure, the rollers manufacturered by our factory all adopt 65 manganese, nine chrome molybdenum, the hardness over 60 level. Using high wear-resistant sole processing technology, improve the service life of 5-8 times. Besides, we have also designed a new type of four-roller briquette press machine, which the pressure is highly improved.

Features of roller charcoal briquettes machine: 1. The charcoal briquettes produced by our machine are smokless, smelless, because we have the high technology liquid binder recipe.2. The service life of barbecue charcoal briquette press machine is prolonged, especially the wear-resistant spare parts.3. The machine is easy operation, easy maintain. 4. This machine is energy saving, can save electricity of 60%, save labors of 2-3 person. Also it is environment protect, it can tatally compress the charcoal powder into charcoal briquettes, less residue.5. The pressure is highly increased because we have not only the four roller type briquette machine, also we have hydraulic type.

Material information of roller charcoal briquette machine:

1. Charcoal powder, carbon dust, bamboo charcoal dust, shisha charcoal powder, coconut shell charcoal powder, jujube charcoal powder, coke charcoal powder, etc. Besides, our charcoal ball briquette machine can be also used to press coal, brown coal, white coal powder or dust, coke powder, coking coal, etc. This equipment is widely used in the field of chemical, refrectories, ceramics, mining, and metallurgy, etc.

2. The inlet material size should be less than 2mm, as you know, the smaller the material, the better the briquettes.

3. There should be a certain proportation of liquid binder of some kinds of materials for shaping the charcoal powder into ball briquettes easily, besides, the binder can also increase the haedness and strength of raw material, and make the briquettes easily burning.

4. The moisture of raw material for briquetting must be moderate like 12-15%.

The shapes and size of charcoal briquettes:

Our roller charcoal briquette machine can compress the charcoal powder into square, oval shape, egg shape, round shape, pillow shape, bread shape, cylinder, bar shape, etc. Also you can make the briquettes hollow in the center. Besides, we can according to your special requirements to make the moulds for you, that means you can set the shape by yourself. Size of briquettes: as your needs within a certain degree (10-80 mm).

Structure and operation principle of roller charcoal briquette machine:

1. Structure:

Our roller charcoal briquette machine is consists of three main parts: the feeding part; transmission part; molding part.

1. The feeding part: it is meanly for charcoal powdery material from hopper evenly into the machine between the rollers for briquetting.

2. The transmission part: it is the main drive system, including the motor, reducer, triangle strip, coupling, driving spindle, open gear.

3. The Molding part: this is the core and also the most important of the machine for press the charcoal powder into charcoal briquettes.2. Operation principle of our roller charcoal briquette machine is as following: the power produced by the motor, through the triangle strip to the reducer, and then is passed to the drive shaft then through a pair of open gear, to enhance the two or four rollers synchronous (constant speed reverse)The simple flow: Motor → Triangle Belt → Reducer → Coupler → Open Gear → Rollers.

Technical parameters:

| Model | Capacity | Roller diam | Motor power | Pressure | Roller speed | Briquette size |

| LT-290 | 1.5-2 t/h | 290 mm | 5.5 kw | 40 | 15-17 r/min | 10-80 mm |

| LT-360 | 2.5-4 t/h | 360 mm | 7.5 kw | 60 | 15-17 r/min | 10-80 mm |

| LT-450 | 4-5 t/h | 450 mm | 15 kw | 60 | 15-17 r/min | 10-80 mm |

| LT-500 | 6-8 t/h | 500 mm | 22 kw | 60 | 15 r/min | 10-80 mm |

| LT-650 | 10-15 t/h | 650 mm | 30 kw | 80 | 15 r/min | 10-80 mm |

| LT-850 | 25-35t/h | 850 mm | 37-45 kw | 100 | 13 r/min | 10-80 mm |

| LT-1000 | 35-40 | 1000 mm | 75-90 kw | 120 | 12 r/min | 10-80 mm |

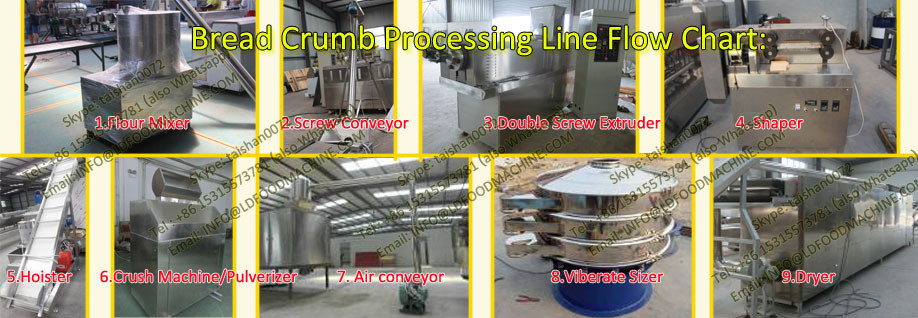

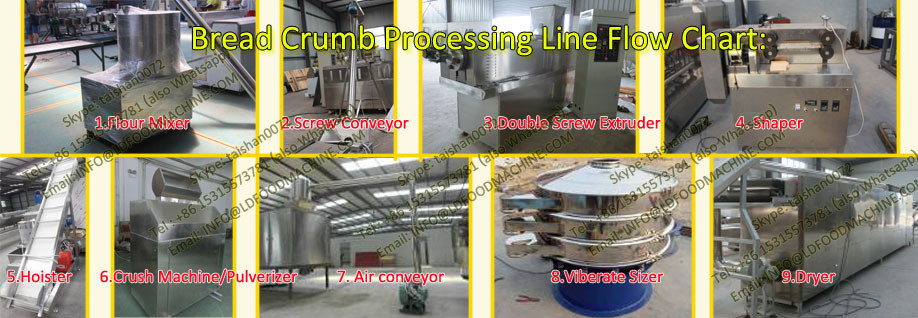

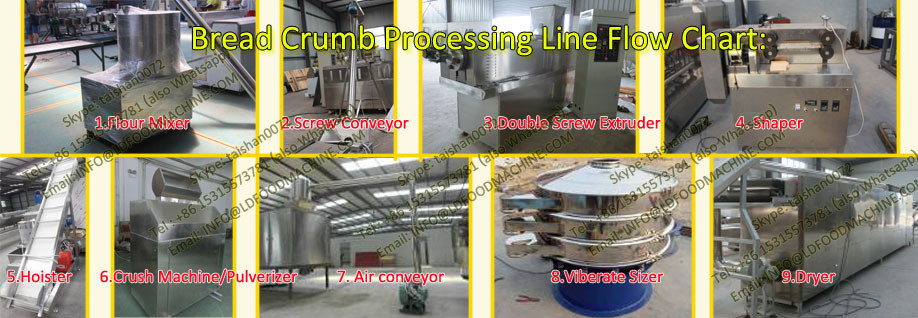

Production line scene of roller charcoal briquette machine:

Besides the roller charcoal briquette machine, we have also the various types of Auto Feeder, Charcoal Powder Separator, Charcoal Crusher, Liquid Binder Mixer, Charcoal Powder Mixer, Conveyor, etc. We can according to your special requirements to provide the suitable equipments for the production line, the whole line can be fully configured to fulfill automatic producing, saving labors, bring as much as profits to you! Also we can provide the selection of adhesive, here we have some reference providing to you as the following: 1) The raw material price is low, cource is rich, convenient for production and processing; 2) The adhesive have good liquidity, strong affinity, can increase the forces between particles; 3) Environmental protection adhesive will not cause pollution to the environment; 4) Try to reduce the ash content increasing (lower mineral content).

The other equipments for the production line:

1) Crusher:

It is used to crush the charcoal into powdery material for briquetting, the size must less than 2mm, and the smaller, the better the charcoal briquettes. This is the first step of making charcoal coal briquettes, this machine is an environmental protect extraction device, which can totally keep the powdery charcoal, not only can save material, but also protect the environment.

2). Binder Mixer and Wheel Mixer:

Binder mixer is an special equipment for this production line, to make the charcoal coal powder easily briquetting, and also increase the hardness of the powdery material. Besides, it ca also make the charcoal briquettes easily burning, and the briquettes are smokeless, non-toxic.

Wheel mixer is to mix the charcoal powder with the liquid binder, but also can grind the charcoal powder to increase its hardness and strength of the charcoal briquettes.

3). Auto Feder:

It is used to feed the raw material into the briquette machine for briquetting evenly, to avoid the conditions that too much material jam the machine or too little material can not briquetting.

Packaging and shapping of our machines:

1. Payment: 30% down payment by TT in advance, or pay directly by Crush, 70% TT balance pay off before delivery.

2. Packaging:

1). All the machines will be wrapped up with plastic film firstly (including the motors)2). The plastic film bag wrapped machine, according to the size and weight to make wooden or iron box, put machine in and fixed the box after loading. (The box material can be made as your requirements)3). The machine parts need to be put in a fixed container, should be fixed well, lest collision and wear, or lost.3. Delivery: after receive your down payment, we will prepare and manufacture all the machines for you, within 15-20 days, all will be finiahsed, we will send pictures to show you, after receive your balance, all the machines will be loaded on board and delivered to you.

Our Services

Our ServicesOur service for our customers:

♥ Before Service:

1. According to our customers special requirements, provide the most suitable project design, process design and the purchase program.

2. Guide customers to choose the best and economical plant, recover investment within short time, and site inspection.

♥ On sale service:

1. Accompany you to check the working conditions of our machines.

2. Inspect the quality of all our machines.

3. Manufacturer the equipments as the contact appears at first time after receive your deposit. Arrange the delivery timely.

♥ After sale service:

1. Send engineers to your site, help you to install and debugging devides, build plant, and training operators, at the same time pass the technology on clay brick production to customers.

2. Guarantee of the equipments quality, maintenance, etc. Solve all the troubles for you timely during your production when receive your call oure-mails.

About our factory:

Through 30 years of development and technology innovation, our Lantian brand roller /honeycomb /extruder /shisha /sawdust charcoal coal briquette machine Mechanical Plant has been developped to a professional manufacturer set design, manufacture, after-sale service as a whole. In order to meet the different requirements of our customers, we designed and researched many types of charcoal process machines, include charcoal & coal briquette machine, shisha & hookah charcoal tablet machines, charcoal & coal extruder machines, and biomass charcoal briquette machines, etc.

Besides, we have also got the CE, ISO, SGS, etc, several patents, and for many years, our machines have been sold home and abroad, and are highly praised by our customers, especially the foreign customers such as Indonesia, Saudi Arabia, Malaysia, India, South Africa, Canada, Australia, Russia, Spain, Greece, Pakiswait, Turkey, Egypt, Sudan, Uzbekistan, Philippines, and other countries.

Other charcoal briquette machines: (If you want to know more about these machines, please contact the following pictures)

Charcoal extruder briquette machine: We have the 140, 180 and the 360 type high pressure charcoal extruder briquette machine, which with two moulding heads, and three stages pressure, so the capacity and density of the charcoal bar briquettes are highly increased. There are several kinds of moulds can produce different types of charcoal bar briquettes, also you can make the charcoal briquettes with or without a hole in the core parts. Briquettes:The briuettes can be round, rectangular, hexagonal, plum-flower, triangular, etc, with our without a hole in the center part.

Honeycomb charcoal briquette machine:The honeycomb charcoal briquette machine is one of our most popular coal and charcoal powder briquette machines. With high capacity, various types of moulds, even can according to customers' special requirements to produce the moulds for you, it is really an charcoal powder processing accustomered equipments.Briquettes:

Honeycomb charcoal briquette machine:The honeycomb charcoal briquette machine is one of our most popular coal and charcoal powder briquette machines. With high capacity, various types of moulds, even can according to customers' special requirements to produce the moulds for you, it is really an charcoal powder processing accustomered equipments.Briquettes:1. Shape: the shapes of honeycomb briquette machine briquettes can be round, cylinder, square, rectangle, polygon, hexagon, sector, etc various, or you can have your own ideal shapes, we can help you make it as your needs.

2. Size: the final size is according to the shape and the machine mould, also you can decide it under certain range.

3. Feature: the outlet briquettes with the advantages of high density, easy fire, long burning time, and non-toxic, smokeless, etc.

Shisha charcoal briquette machine:On the base of Mechanical type shisha charcoal and coal briquette machine, we have designed and manufactured the Hydraulic type shisha charcoal powder briquete machine, it with an operation table, oil pump, so that the pressure and working performance of this machine is highly improved. It is easy to operate, maintain, and can be used at any working conditions.Outlet shisha charcoal tablets:

Shisha charcoal briquette machine:On the base of Mechanical type shisha charcoal and coal briquette machine, we have designed and manufactured the Hydraulic type shisha charcoal powder briquete machine, it with an operation table, oil pump, so that the pressure and working performance of this machine is highly improved. It is easy to operate, maintain, and can be used at any working conditions.Outlet shisha charcoal tablets:1) Size and shapes: Size: round: 20-45mm, square: 15-55mm Shape: round, square, restabgle, triangle, cylinder, diamound, cone, etc

2) Characteristics: The shisha tablet briquettes use quick burning charcoal technology, can burn from the top to down. Firepower fierce, smokeless, tasteless, non-toxic, long burning time.

Sawdust charcoal briquette machine:

Rice husk briquette machine is mainly used for pressing the organic powdery material into biomass briquettes under high pressure. It is a kind of enviroment protect and energy-saving product which can turn "organic waste" into "wealth". According to the size of moulds, our machines can be devided into 50, 60, 70, 80, etc, several different types.

It adopts various types of biomass powdery material, under the action of screw propeller and heating rings, to press the biomass materials into solid stick types of briquettes with or without a hole in the core section.

Briquettes:

1) According to our machine, the final briquette diameter can be 40mm/45mm/ 50mm/60mm/7Wm/80mm. Or just according to your requirements. The shapes can be round, square, hexagon, quincunx, etc.

2) The length is also adjustable, and we have also the automatic cutting machine for you!

3) You can make the briquettes with or without a hole in the center.

Jinan Joysun Machinery Co., Ltd. est une grande entreprise par actions, axée sur la production d'Lantian brand roller /honeycomb /extruder /shisha /sawdust charcoal coal briquette machine, intégrée à la recherche scientifique, à la production et aux ventes. La société est située dans la zone industrielle de Shandong salut-technologie, couvre une superficie de 50.000 mètres carrés, avec 15.000 mètres carrés deux standard usine industrielle lourde, plus de 160 ensembles toutes sortes de traitement des métaux de grande et moyenne taille, soudage, équipement d'assemblage .Jinan Joysun Machinery Co., Ltd. attache une grande importance aux échanges techniques et à la coopération internationale, a présenté la technologie de pointe sur et artisanat des États-Unis, Allemagne, Australie et autres pays, établit les lignes de production avancées internationales AAAA et base d'essai moderne de première classe.

Jinan Joysun Machinery Co., Ltd. basé sur une forte résistance technique, l'amélioration des méthodes de détection, excellent système d'assurance qualité pour assurer que « la qualité d'abord, le premier client », responsable de l'installation et la mise en service, les services techniques et des produits de formation technique, après l'installation est terminée je vais 9999999 techniciens vos opérations de production de l'entreprise du personnel de l'équipement de formation professionnelle et technique et des démonstrations en direct.