Product Description

PJapanese bread crumb making machine bread crumbs process line Bread Crumbs making Machine:

1.Breadcrumb machine description

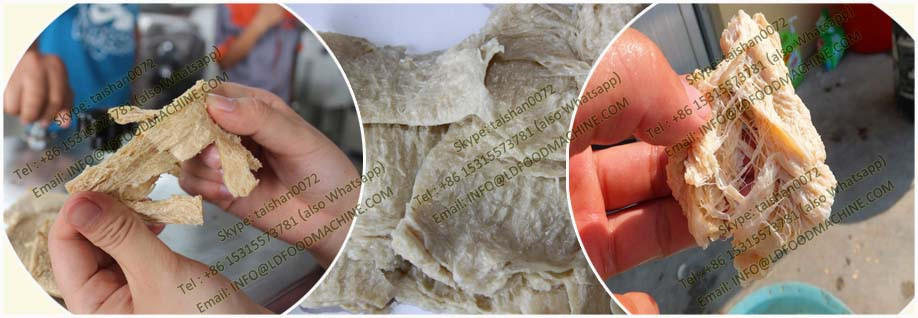

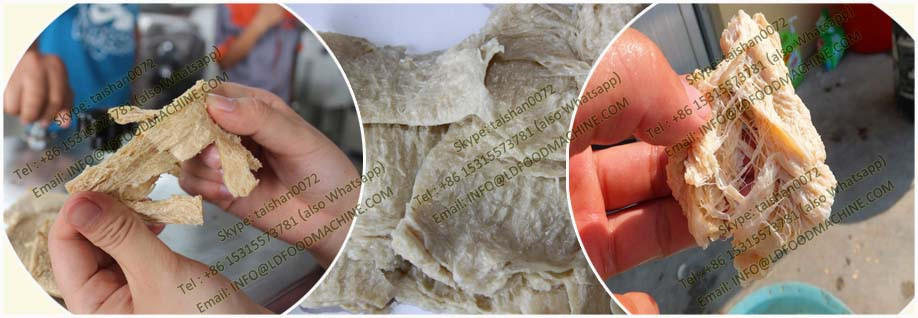

a.PJapanese bread crumb making machine bread crumbs process line breadcrumbs machine is mainly used for fried beefsteak and drumstick as frying dressing. The long and sliver-shaped breadcrumbs are of porous structure inside .After frying ,the crumbs become straight up bit xby bit.They are not only puffed and nice in appearance but also crisp and delicate in taste.

b.PJapanese bread crumb making machine bread crumbs process line breadcrumbs machine is specially designed and developed according to market demand .The whole line can be finished from the raw material ,extrusion ,drying to finished products automatically

Factory direct sale pJapanese bread crumb making machine bread crumbs process line breadcrumbs machine / dry and fresh electrode breadcrumbs

2.Application: food additive for deep fried food, and mainly for frying food surface, such as: fried chicken, fish, seafood (shrimp), chicken, chicken wings, onion rings, etc. Its feature is crispy soft, tasty, delicious and nutritious.

3. Raw material: for bread crumbs production. It is from powder for wheat flour to bread crumbs automatically. No bread produced during the whole process. So no bread crust appeared. The final product is bright white and with good texture.

4. The output three types with different output :150kg/h.250kg/h 500kg/h

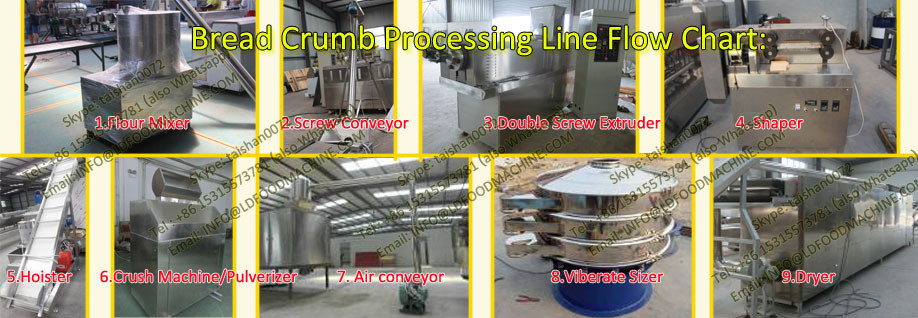

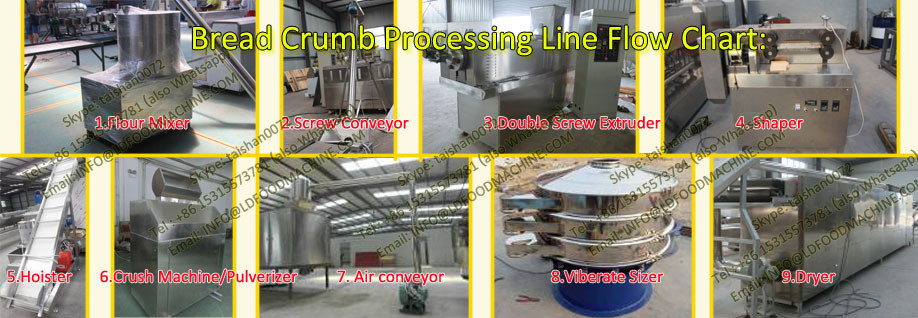

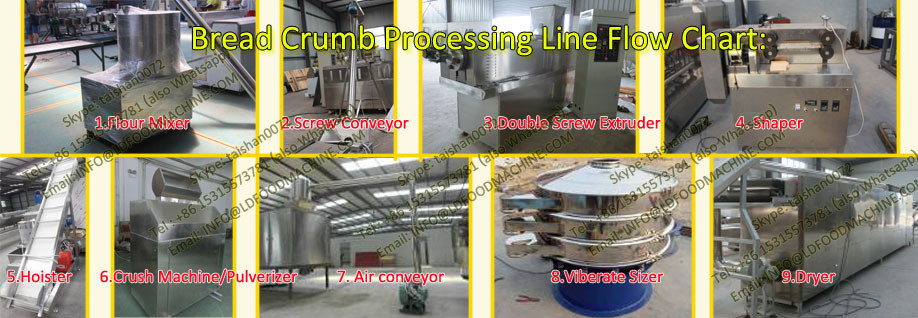

5. Flow chart:

Mixer-Screw conveyor-Twin screw extruder-Cutter-Hoister-Humid crusher-Air conveyor-Multi-layer roasting oven-Air conveyor(or Japanese bread crumb making machine bread crumbs process line feeding machine)-Grading sifter.

6.The parameter of the PJapanese bread crumb making machine bread crumbs process line Bread Crumbs making Machine:

Jinan Saibainuo Machinery Co., Ltd for food machine manufacturering in China since 2004, offer competitive advantage machines, so with us your money in safe, your business in safe.

The inside structure of our twin screw extruder.

Our multi-layer dryer.

Detailed Images

Detailed Images

Name: high speed mixer

Dimension(m): 1.1×0.8×1.4

Motor Power: 4KW

Speed: 400rpm

Throughput: 30kg per loading (5-6 minutes per loading)

Functions:

Mix powder raw material with water

Features:

1. stainless steel material(1.5mm).

2. new handle-opened design of discharge holes,no material leak

3.High speed can mix material better than other slow mixer.

Name: screw conveyor

Dimension(m): 3.2×0.6×0.7

Motor Power: 1.1KW

Screw speed: 300rpm

convey height range:1.5~2.5M

barrel diameter: Φ141mm

Function:

Power material can be conveyed in the stainless steel roller to the feed machine of extruder without leaking, dust and pollution;

Name: twin screw extruder

Dimension(m): 2.6×1.0×1.3

Total power: 37kw

Main Motor Power:22KW

Feeder motor:0.75kw

Cutting motor: 1.5kw

Heating power:10kw

Extruder diameter:Φ65 mm

Function:

Extrude and cook raw material into different size and shapes

Features:

Screw material is 38CrMoAl with nitriding treatment, the hardness is

60HRC.. The barrel also use good material, hardness is 55HRC.

The gear box has forced lubrication system.

All motors can be adjusted the speed by Inverter.

The Extruder can change different molds to produce different Shapes product.

Name: Vibrating machine

Dimension(m): 1.6×0.7×0.5

Motor Power: 0.4KW

Functions:

To vibrate the bread crumbs to remove the powder mixed in the bread crumbs.

Name: multi-layer dryer

Dimension(m): 5.4×1.3×1.8

Heating Power:27kw

Motor power:0.75kw

Belt speed:0.1-10M/minute

Temperature: 20-200℃

Function:

There are Three layers inside,each layer is 5 meters long, it can save space and energy. Electricity heating,used to bake and dry food.

Features:

The net belt running speed can be controlled by Inverter, to change the food drying time in the dryer.

Heating adopts the electric heat tube.

It has automatic temperature Control system.

The belt and the cover are all stainless steel.

Name: sifter

Dimension(m):1.1×0.8×1

Motor Power:0.37 KW

Function:

To separate the bread crumbs into two kinds of size.

Feature:

It has different size sieves

We can change the sieves to separate the bread crumbs into different size.

Certifications

Certifications

Our Service

Our Service

Packing & Delivery

Packing & Delivery

Related Products

Related Products

Pasta food making machine

98.8% Response Rate

Kurkures cheetos machine

99.8% Response Rate

Pet food production machine

98.6% Response Rate

Jinan Joysun Machinery Co., Ltd. est une grande entreprise par actions, axée sur la production d'Japanese bread crumb making machine bread crumbs process line, intégrée à la recherche scientifique, à la production et aux ventes. La société est située dans la zone industrielle de Shandong salut-technologie, couvre une superficie de 50.000 mètres carrés, avec 15.000 mètres carrés deux standard usine industrielle lourde, plus de 160 ensembles toutes sortes de traitement des métaux de grande et moyenne taille, soudage, équipement d'assemblage .Jinan Joysun Machinery Co., Ltd. attache une grande importance aux échanges techniques et à la coopération internationale, a présenté la technologie de pointe sur et artisanat des États-Unis, Allemagne, Australie et autres pays, établit les lignes de production avancées internationales AAAA et base d'essai moderne de première classe.

Jinan Joysun Machinery Co., Ltd. basé sur une forte résistance technique, l'amélioration des méthodes de détection, excellent système d'assurance qualité pour assurer que « la qualité d'abord, le premier client », responsable de l'installation et la mise en service, les services techniques et des produits de formation technique, après l'installation est terminée je vais 9999999 techniciens vos opérations de production de l'entreprise du personnel de l'équipement de formation professionnelle et technique et des démonstrations en direct.