Best selling widely used charcoal briquette machine

Product Description360 HIgh Pressure Charcoal Briquette Machine:

Brief introduction of widely used charcoal briquette machine:

Our widely used charcoal briquette machine is mainly used to use screw extrusion principle to process coal and charcoal powder mixed with a certain proportion of liquid binder into different shapes and size of briquettes, with certain strength, also you can choose to make the briquettes with or without a hole in the core part. The utilization of this machine can make full use of the coal or charcoal powder material, you do not need to mix the material with lime, it reduces the cost of fuel, and improves the calorific value of raw material.

Material information about the widely used charcoal briquette machine:

1. Applicable raw material: coal powder, coal dust, coke powder, brown coal powder, coal waste, also charcoal powder of biomass material such as: sawdust, wood shavings, wood wastes, branches, rice husk, peanut shell, coconut shell, begasse, sediment, cotton stem, corn stalk, corn cob, etc. After carbonization, the charcoal can be used as raw material.

2. The inlet particle size of raw material: it must be less than 2mm.

3. You must add a certain proportion of liquid binder of some kinds of materials for shaping easily, besides, the binder can also increase the hardness of material, and make the briquettes easily burning.

4. The moisture of materials for briquetting must be moderate, the water content should be 12-15%.

Installation and adjustment and maintain of widely used charcoal briquette machine:

1. All the part should be cleaned and checked before installation.

2. Install the machines on the level ground, and better on the concrete floor.

3. Before trying the machine, you have to add oil into the lubricant parts.

4. Check whether there is loosen parts, if yes, tight it directly.

5. Inching the machine, and see whether there are clutters and unnormal sounds. If there is no, we can start the machine completely.

6. Driving the machine to run it without any material in for about 3-5 minutes, after make sure the machine works normal and good, we can put the materials in it for production.

7. If the feed opening apperas blocking, use a wooden stick to unclock, and mustn't use the metal of steel stick.

8. Add the oil for the transmission and rotating parts regularly. The temperature of bearing parts shold be less than 60 celsius degree.

9. Stop feeding the materials and make sure there is no any material in the cylinder before stopping the mahcine. Remove the machine head, clean it and theninstall it for next time using.

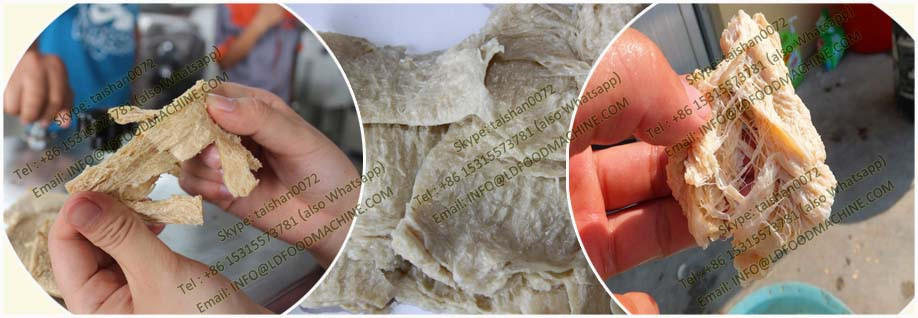

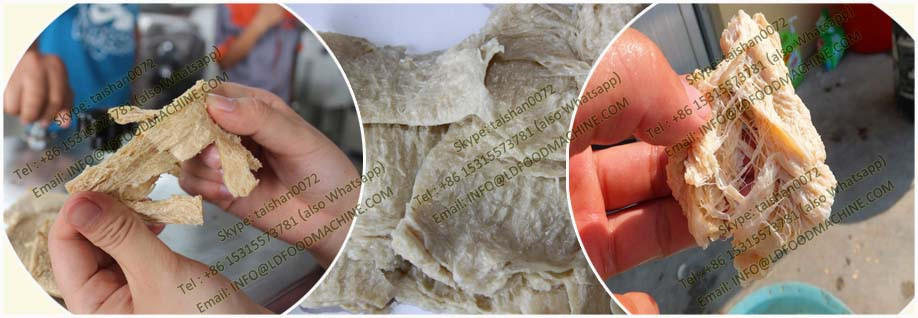

Briquettes of widely used charcoal briquette machine:

Our machine can press the coal or charcoal powery material into a certain density stick or bar shaper briquettes (can be round, rectangular, hexagonal, plum-flower, triangular, etc.). It is mostly used for producing barbecue or shisha charcoal briquettes. The following are some of the samples, and also you can have your own ideal shapes, we can manufacture it accoeding to your needs.

Burning conditions of widely used charcoal briquette machine:

The Features of widely used charcoal briquette machine:

1. First carbonization, and then briquetting, reduces the procedures to 3 stages from the 5 process of firstly briquetting and then carbonization.

2. The service life is greatly prolonged, especially the quick-wear parts, the service life is increased from 40 hours to 4000 hours.

3. The cost of electricity is reduced by 60%.

4. The capacity is increased by 2-3 times, the cost of making charcoal briquettes is reduced of 200 USD per tons.

5. The operation of the machines is become very easy, we show you directly in front of you, or by videos.

6. The weak charcoal is turned into high quality charcoal briquettes, the high quality charcoal is turned into special high quality charcoal.

7. The weak charcoal content is increased from 60% to 70-75%, the high quality charcoal content is increased more than 83%, make the market highly expanded.

Technical parameters of widely used charcoal briquette machine:

1. We have several types of coal and charcoal briquettes making machine, such as 140, 180, 360, etc, several models.

2. The Model 360 type coal and charcoal briquetes making machine is newly designed on the base of the 140, 180 types.

3. It has 3 electric motors, which can produce 3 stages pressure, which is much higher than the other types. Besides, it with two discharging moulds can stgrengthly producing the briquettes with high density, also its capacity is twice than the old types. More over, you can directly produce two kinds of briquettes with two different shapes at the same type, what you need is only to change the moulds as your needs.

| Model | Capacity | Power | Reducer | Speed of Mainshaft | Specifications | Packaging Size |

| LTM-140 | 1-2 T |

7.5/11 kw | ZQ 350 | 46-60 TURN /MIN | Φ 20-40 | 1900*1100*1200 mm |

| LTM-180 | 2-3 T | 11/15 kw | ZQ 400 | 46-60 TURN /MIN | Φ 20-60 | 2100*1500*1200 mm |

| LTM-360 | 3-4 T | 15 kw | ZQ 650 | 46-60 TURN /MIN | Φ 20-80 | 2550*2160*1300 mm |

Auto cutter for cutting the briquettes automatically:

Here in our factory, we have designed a kind of auto cutter for automatically cutting the output briquettes into different size according to your needs. The machine with an stainless steel for cutting the briquettes, also there are two (yellow) sensors (as the following pictures show) in front of the wheel gear on the two sides, when the charcoal briquettes out off the wheel gear, and reaching to the sensors,

will cause the motor to drive the wheel gear running and cut the charcoal briquettes.

Auto cutter together with the briquette machine:

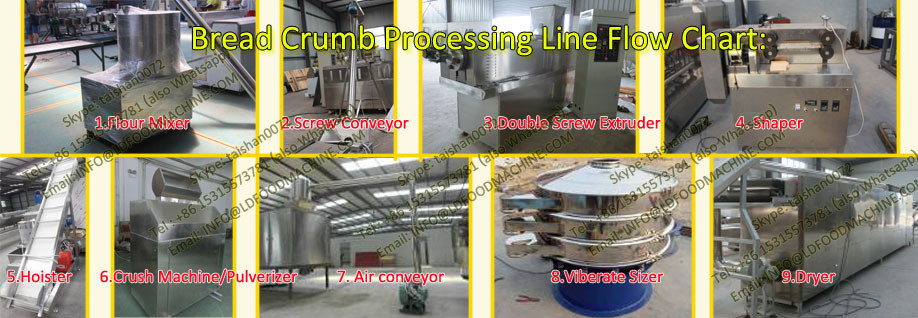

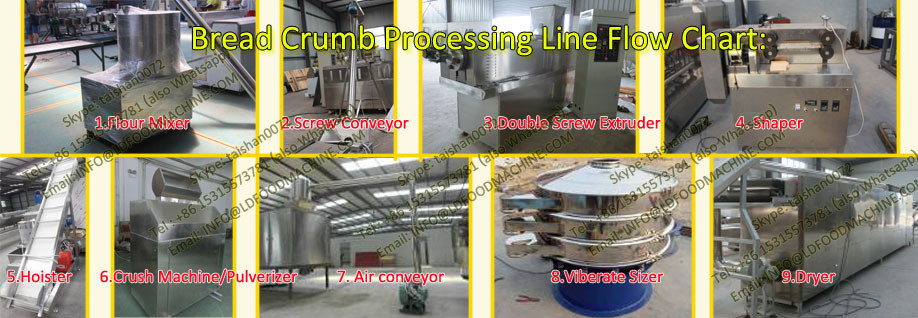

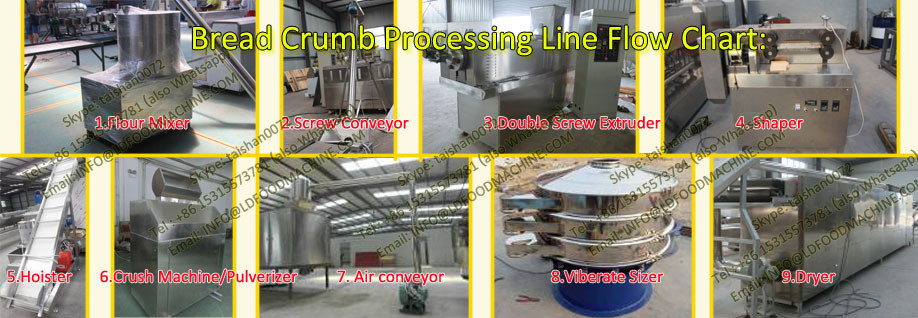

The assistant equipments and procedures of widely used charcoal briquette machine:

Besides the widely used Charcoal Briquettes Machine, we have also the Crusher, Liquid Binder Mixer, Mixer, Auto Feeder, Belt Conveyor, Briquette Dryer, etc.

The procedures are as the following:

1. Firstly, you need to crush the powdery material into small size: which should be less than 2mm.

2. Secondly, you need to make liquid binder, to increase the hardness of powdery material, and also make the raw material easily burning.

3. Thirdly: you have to mix the liquid binder with the powdery material evenly for that the powdery material can be easily and better pressed into briquettes.

4. Forth: you can feed the raw material into the briquette machine directly, or use the auto feeder to feed the material evenly into the briquette machine.

5. Fifth: you shall dry the coal or charcoal briquettes by our box-type dryer, or dry it under the sunshine if it is dtrong enough.

Packaging and shapping of our machines:

1. All the machines will be wrapped up with plastic film first (including the motor).

2. The plastic film bag wrapped machine, according to the size and weight to make wooden or iron box, put machine in and fixed the box after loading. (The box material can be made as your requirements)

3. The machine parts need to be put in a fixed container, should be fixed well, lest collision and wear, or lost.

Our service for our customers:

♥ Before Service:

1. According to our customers special requirements, provide the most suitable project design, process design and the purchase program.

2. Guide customers to choose the best and economical plant, recover investment within short time, and site inspection.

♥ On sale service:

1. Accompany you to check the working conditions of our machines.

2. Inspect the quality of all our machines.

3. Manufacturer the equipments as the contact appears at first time after receive your deposit. Arrange the delivery timely.

♥ After sale service:

1. Send engineers to your site, help you to install and debugging devides, build plant, and training operators, at the same time pass the technology on clay brick production to customers.

2. Guarantee of the equipments quality, maintenance, etc. Solve all the troubles for you timely during your production when receive your call oure-mails.

Company Information

Company InformationAbout our factory:

Through 30 years of development and technology innovation, our Best selling widely used charcoal briquette machines Mechanical Plant has been developped to a professional manufacturer set design, manufacture, after-sale service as a whole. In order to meet the different requirements of our customers, we designed and researched many types of charcoal process machines, include charcoal & coal briquette machine, shisha & hookah charcoal tablet machines, charcoal & coal extruder machines, and biomass charcoal briquette machines, etc.

Other charcoal briquette machines: (If you want to know more about these machines, please contact the following pictures)

Charcoal roller briquettes making machine: Charcoal roller briquettes machine is mainly used to press coal or charcoal powder into ball shape briquettes. The raw material also can be white coal, brown coal, coke powder, coking coal, etc. The shape of the briquettes can also be square shape, oval shape, egg shape, round shape, pillow shape, bread shape, cylinder, bar shape, etc, more over, we can accoding to your special requirements to make the moulds for you!

Shisha Charcoal Tablet Briquette Machine:On the base of Mechanical type shisha charcoal tablet press machine, we have designed and manufactured the Hydraulic type shisha charcoal tablet press machine, it with an operation table, oil pump, so that the pressure and working performance of this machine is highly improved. It is easy to operate, maintain, and can be used at any working conditions.

Shisha Charcoal Tablet Briquette Machine:On the base of Mechanical type shisha charcoal tablet press machine, we have designed and manufactured the Hydraulic type shisha charcoal tablet press machine, it with an operation table, oil pump, so that the pressure and working performance of this machine is highly improved. It is easy to operate, maintain, and can be used at any working conditions.

Honeycomb Charcoal Briquettes Machine:The honeycomb charcoal briquettes making machine is one of our most popular coal and charcoal briquettes making machines. With high capacity, various types of moulds, even can according to customers' special requirements to produce the moulds for you, it is really an charcoal powder processing accustomered equipments. Shapes: round, cylinder, square, rectangle, polygon, sector, etc, or as your requirements.

Honeycomb Charcoal Briquettes Machine:The honeycomb charcoal briquettes making machine is one of our most popular coal and charcoal briquettes making machines. With high capacity, various types of moulds, even can according to customers' special requirements to produce the moulds for you, it is really an charcoal powder processing accustomered equipments. Shapes: round, cylinder, square, rectangle, polygon, sector, etc, or as your requirements.

Any question, welcome to contatc me freely at any time you need!Skype: vickyzhang336Mobile: 0086--15038259123QQ or Best selling widely used charcoal briquette machines 531475863

Any question, welcome to contatc me freely at any time you need!Skype: vickyzhang336Mobile: 0086--15038259123QQ or Best selling widely used charcoal briquette machines 531475863

Jinan Joysun Machinery Co., Ltd. est une grande entreprise par actions, axée sur la production d'Best selling widely used charcoal briquette machines, intégrée à la recherche scientifique, à la production et aux ventes. La société est située dans la zone industrielle de Shandong salut-technologie, couvre une superficie de 50.000 mètres carrés, avec 15.000 mètres carrés deux standard usine industrielle lourde, plus de 160 ensembles toutes sortes de traitement des métaux de grande et moyenne taille, soudage, équipement d'assemblage .Jinan Joysun Machinery Co., Ltd. attache une grande importance aux échanges techniques et à la coopération internationale, a présenté la technologie de pointe sur et artisanat des États-Unis, Allemagne, Australie et autres pays, établit les lignes de production avancées internationales AAAA et base d'essai moderne de première classe.

Jinan Joysun Machinery Co., Ltd. basé sur une forte résistance technique, l'amélioration des méthodes de détection, excellent système d'assurance qualité pour assurer que « la qualité d'abord, le premier client », responsable de l'installation et la mise en service, les services techniques et des produits de formation technique, après l'installation est terminée je vais 9999999 techniciens vos opérations de production de l'entreprise du personnel de l'équipement de formation professionnelle et technique et des démonstrations en direct.